Industrial Belts

Industrial Belts

Shah Industrial is a leading importer and trader of a comprehensive range of industrial belts, including all types of Flat Belts, Conveyor Belts, Timing Belts, and specialized imports like NITA JAPAN belts. Our belts are engineered to provide reliable power transmission and material handling solutions across various industries.

We offer a diverse selection to meet specific application requirements, ensuring optimal performance, durability, and efficiency for your machinery. From heavy-duty power transmission to precision timing, our industrial belts are designed to withstand challenging operating conditions and deliver consistent results.

-

Versatile

Applications -

High

Performance -

Reliable

Solutions

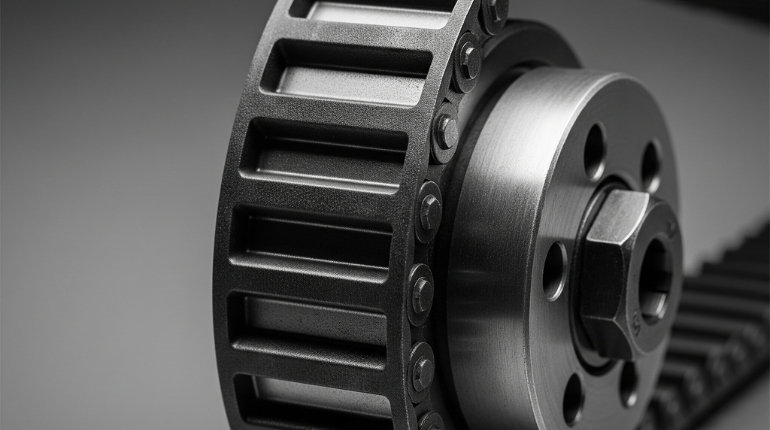

Timimg Belt

Timing belts are essential for precise power transmission and are categorized based on material, tooth profile, and construction:

- Rubber Belts: Affordable, reinforced with fiberglass or steel cords.

- Polyurethane Belts: High strength, wear-resistant, ideal for harsh conditions.

- Trapezoidal: Precise timing, minimal backlash (e.g., MXL, XL, L).

- Curvilinear: High torque, smooth operation (e.g., HTD series: 3M–14M).

- Modified Curvilinear: Balanced torque & precision (e.g., S8M).

- Double-Sided Belts: Teeth on both sides.

- Coated/Fabric Belts: For durability and high acceleration use.

- High Torque Belts: e.g., HTD, STD, RPP Gold/Silver series.

- HTD: 3M, 5M, 8M, 14M, D5M, MHP, HL

- STD: S5M, S8M, S14M, S8MHP

- RPP: SLV5, SLV8, SLV14

- Inch Sizes: MXL, XL, L, XH, XXH

Material:

Tooth Profiles:

Other Types:

Common Profiles:

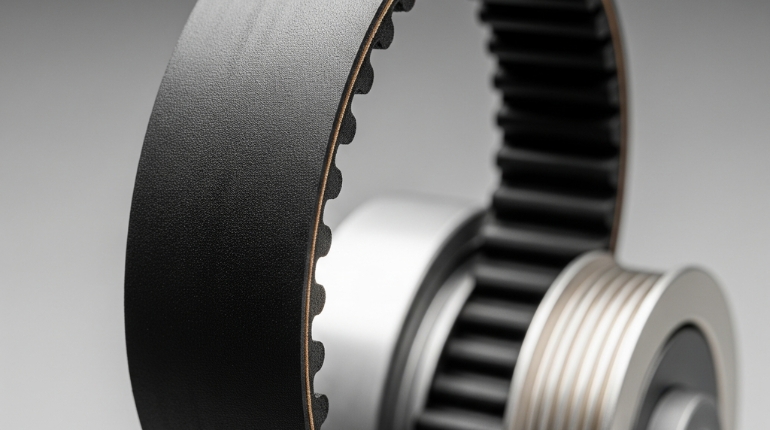

Poly Chain Belt

Poly Chain belts are high-performance synchronous belts designed for high torque and high-speed applications, often replacing traditional roller chains.

- Poly Chain GT: High torque for low-speed applications with long service life.

- Poly Chain Carbon: Carbon fiber cord for higher strength and stability.

- Poly Chain GT Carbon: Combines GT’s power with carbon’s durability for compact, high-performance use.

- High Torque & Speed: Suitable for demanding industrial and power tool applications.

- Durable & Strong: Made from polyurethane and aramid or carbon cords, offering wear and chemical resistance.

- Maintenance-Free: No lubrication or re-tensioning required.

- Temperature Resistant: Performs reliably in extreme hot or cold conditions.

- Roller Chain Alternative: Lighter, quieter, and requires less space and upkeep.

- Robotics, machine tools, medical equipment, power tools, data storage, and industrial machinery.

Types:

Features:

Applications:

Cut Belt (XP V-Belt)

XP V-belts, also called narrow V-belts, are designed for high-power and high-speed transmission with superior durability and heat resistance.

- Poly Chain GT: High torque for low-speed applications with long service life.

- Poly Chain Carbon: Carbon fiber cord for higher strength and stability.

- Poly Chain GT Carbon: Combines GT’s power with carbon’s durability for compact, high-performance use.

- High Power: Transmits up to 3× more power than standard V-belts.

- High Speed:Operates up to 50 m/s peripheral speed.

- Temperature Resistant: Handles -40°C to +130°C with ease.

- Durability: Abrasion-resistant and often maintenance-free.

- Various Profiles: Available in XPZ, XPA, XPB types.

- XPZ: 9.7 x 8 mm – Ideal for compact, high-speed drives.

- XPA: ~13 x 10 mm – Suitable for general high-power use.

- XPB: ~16.3 x 13 mm – Highly robust, resistant to oil and heat.

- Industrial machinery, compressors, pumps, agricultural equipment, and other high-speed/high-power systems.

Types:

Features:

Common Profiles:

Applications:

Caterpillar Belt

Caterpillar belts are used in power transmission and conveyor systems, available in various sizes and materials to suit different industrial needs.

- HTD Belts: Toothed belts for high torque transmission applications.

- V-Belts: Trapezoidal belts used in various power transmission setups, available in classical and narrow profiles.

- Belt Length: Measured using the existing belt or string method.

- Belt Width:Crucial for proper fit, varies by belt type and drive system.

- Material: Commonly rubber or leather, selected based on environment and application.

- Drive Type: Conveyor or high-torque systems influence belt choice.

- Application: Depends on machinery type and material handling requirements.

- XPZ: 9.7 x 8 mm – Ideal for compact, high-speed drives.

- XPA: ~13 x 10 mm – Suitable for general high-power use.

- XPB: ~16.3 x 13 mm – Highly robust, resistant to oil and heat.

- Industrial machinery, compressors, pumps, agricultural equipment, and other high-speed/high-power systems.

Types:

Features:

Common Profiles:

Applications:

Variable Speed Belt (CVT Belt)

Variable speed belts, or CVT belts, are specialized V-belts used for applications requiring smooth speed variation without changing the input speed.

- Variable Speed: Allows flexible output speed while input remains constant.

- Raw Edge Cogged Design: Core component in Continuously Variable Transmission systems.

- Durable & Flexible: Suitable for small pulleys with stable power transmission.

- Industrial Machinery,Vehicles

Features:

Applications:

-

What types of Industrial Belts do you offer?

We offer a wide array of industrial belts, including Flat Belts (Nylon sandwich, Rubber sandwich, Canvas sandwich), various types of Conveyor Belts (PTFE, Rubber, PVC, PU), and Timing Belts (rubber synchronous, polyurethane synchronous, trapezoidal, curvilinear). We also import specialized belts like NITA JAPAN. -

What industries benefit from your Industrial Belts?

Our industrial belts serve a vast range of industries, including all major industries in Gujarat, textile industries, cable industries in Surat & Silvassa, mining, agriculture, food processing, packaging, warehousing, logistics, and many other manufacturing and assembly lines requiring efficient material handling and power transmission. -

How do I choose the right industrial belt for my application?

Choosing the right belt depends on several factors, including the type of material being conveyed or the power transmission requirements, operating environment (temperature, chemicals), load capacity, and speed. Our experts can assist you in selecting the ideal belt based on your specific application to ensure optimal performance and longevity.